Wastewater treatment is a challenge in and of itself, but dealing with the leftover sludge presents a whole new set of issues. When managed poorly, sludge management can be very costly, bad for the environment, and make a real stink – literally.

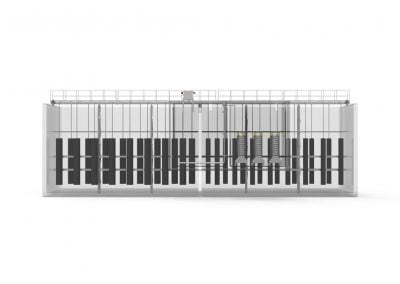

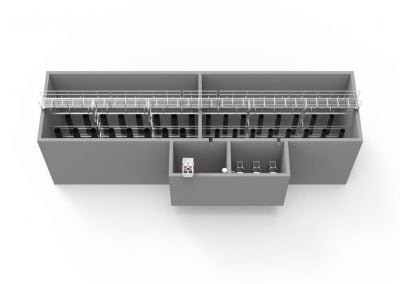

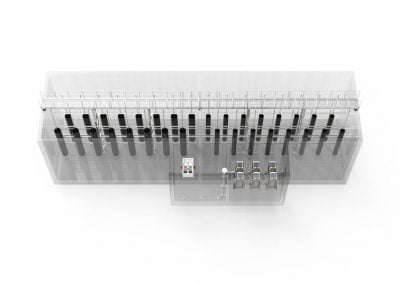

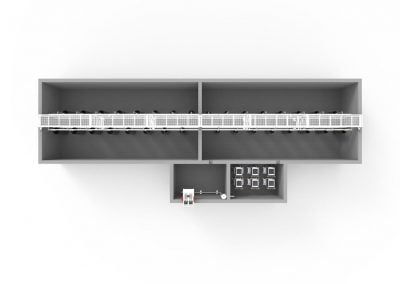

solidBLOX transforms wastewater treatment plants by optimizing sludge handling process while lowering effluent NH3 and TP. When coupled with aerobic digestion, solidBLOX eliminates foul odors while producing reuse quality effluent, which is good for all of us.

By thickening to 3%, solidBLOX also can reduce sludge hauling requirements, reducing both cost and pollution. An aerobic digester can now be operated at 3% solids, reducing the size of a conventional aerobic digester by many fold. In addition, by using SiC to thicken solids, polymer addition is eliminated, saving plants a ton of money and hassle. Last, but certainly not least, solidBLOX helps make natural organic fertilizer, which is good for all of us.

solidBLOX IS USED IN THE FOLLOWING MARKETS

- Aerobic digestion plants

- WWTP with high hauling costs

- WWTP with tight TN and/or TP limit

BENEFITS OF SOLIDBLOX ARE

- Class B solids with a lower footprint and energy consumption

- Thickening to >3% solids without the use of polymers

- Lower sludge hauling costs

- Elimination of foul odors associated with conventional aerobic digestion

- Reuse quality effluent that compliments a BNR process

DID YOU KNOW?

solidBLOX can

treat >3% solids! That’s like filtering a milkshake.