MBRs are a fantastic technology that we need – it provides a level of wastewater treatment that no other technology can but they sometimes face operational challenges or difficulties. Let’s remember that membranes in an MBR are in a turbulent, high mixed liquor, high fouling environment which can place tremendous stress on any membrane. ecoBLOX systems are able to endure and withstand the stresses of an MBR environment by utilizing SiC membranes that are a rock!

ecoBLOX systems are truly resilient. ecoBLOX systems have the widest operational window meaning they can adapt, without failure, to changes in process conditions. This ability to adapt ensures smooth operation, long membrane life, and low life cycles costs. ecoBLOX plants are also a great fit for installations with seasonal flow, like ski resorts, where temporarily shutting down the system for an extended period of time makes sense.

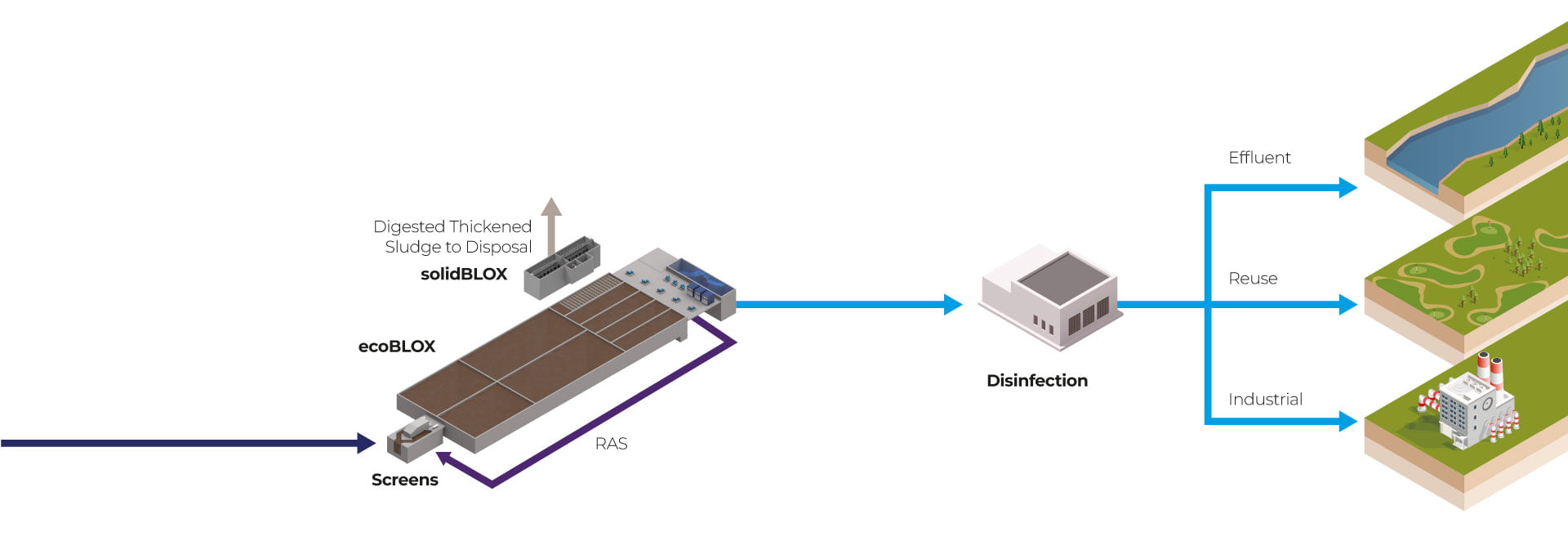

With an extremely small footprint and flexible design, ecoBLOX systems can be easily integrated into existing treatment plants. That same flexibility, coupled with smart automation and process design make it perfect for greenfield installations.

ecoBLOX IS USED IN THE FOLLOWING MARKETS:

- Replacement of struggling polymeric MBR plants

- Retrofit of conventional activated sludge (CAS) plants

- Greenfield plants

- Packaged plants

BENEFITS OF ECOBLOX

- Increase capacity of existing systems, including MBR plants

- 100% recoverability

- Widest operating window

- Membrane life is decoupled from chemical cleaning

- Easy to operate and maintain

- Easily placed offline dry with no special preservation

limitless

possibilities

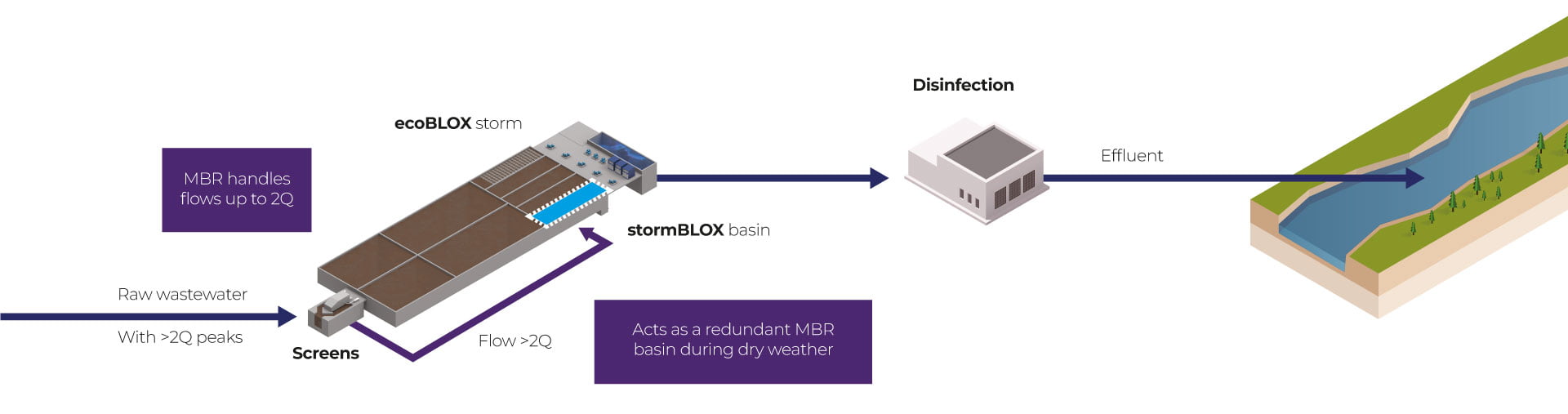

Our ecoBLOX-storm is the combination of ecoBLOX and stormBLOX technologies. When coupled together, ecoBLOX-storm systems are able to address a long-standing problem for MBRs: how to treat peak flows greater than 2Q cost effectively. By integrating two unique technologies into a single system, ecoBLOX-storm is able to address high peaking factors economically. Not only does the integration of stormBLOX into an ecoBLOX address high peaks, it also provides flexibility of operation and maintenance with redundant membranes. Our stormBLOX are a great option to address high peak flows for any treatment plant – see more about stormBLOX on our website (sicblox.ovivowater.com).

extreme peak flow management for mbr

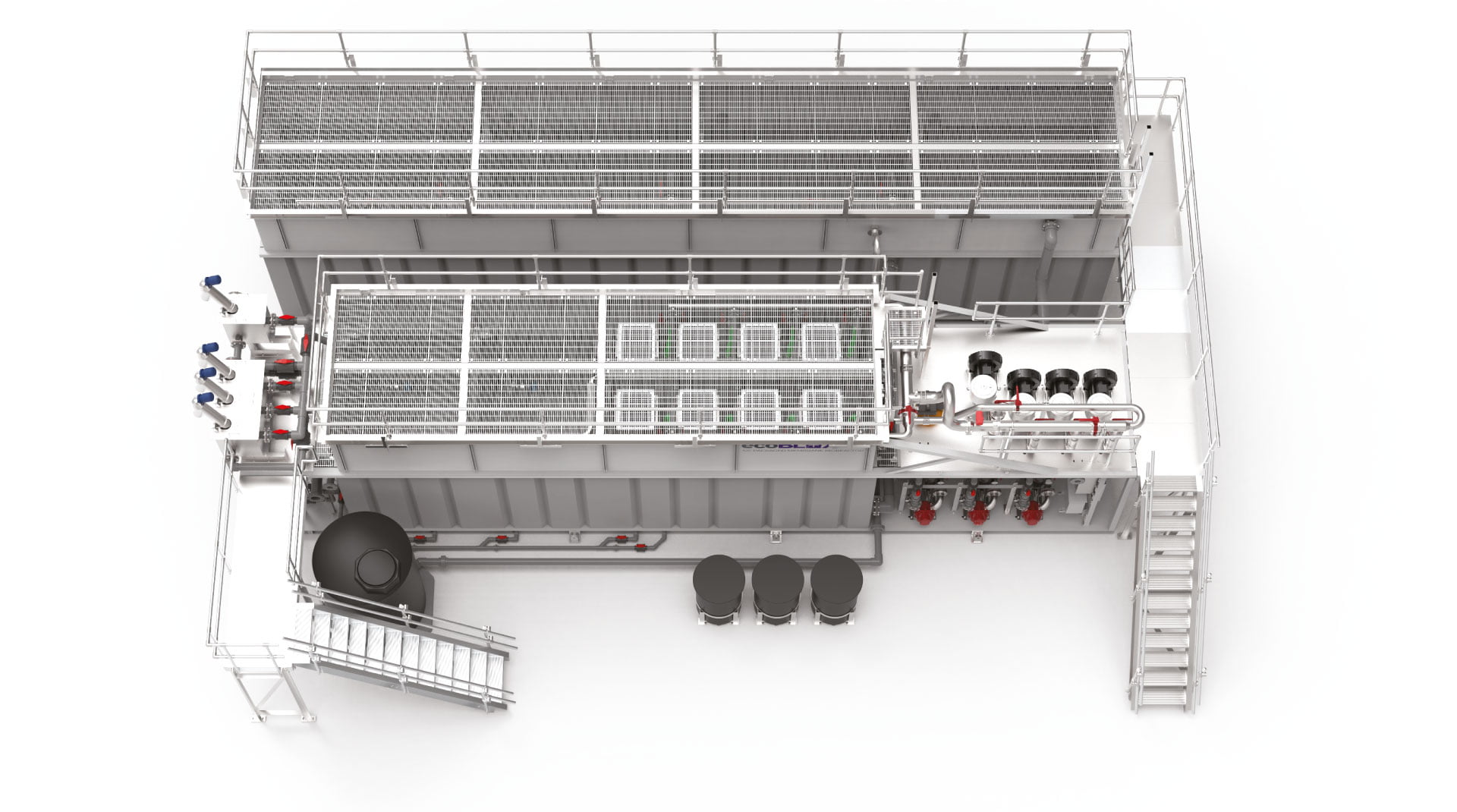

bio

HYDRAULICS

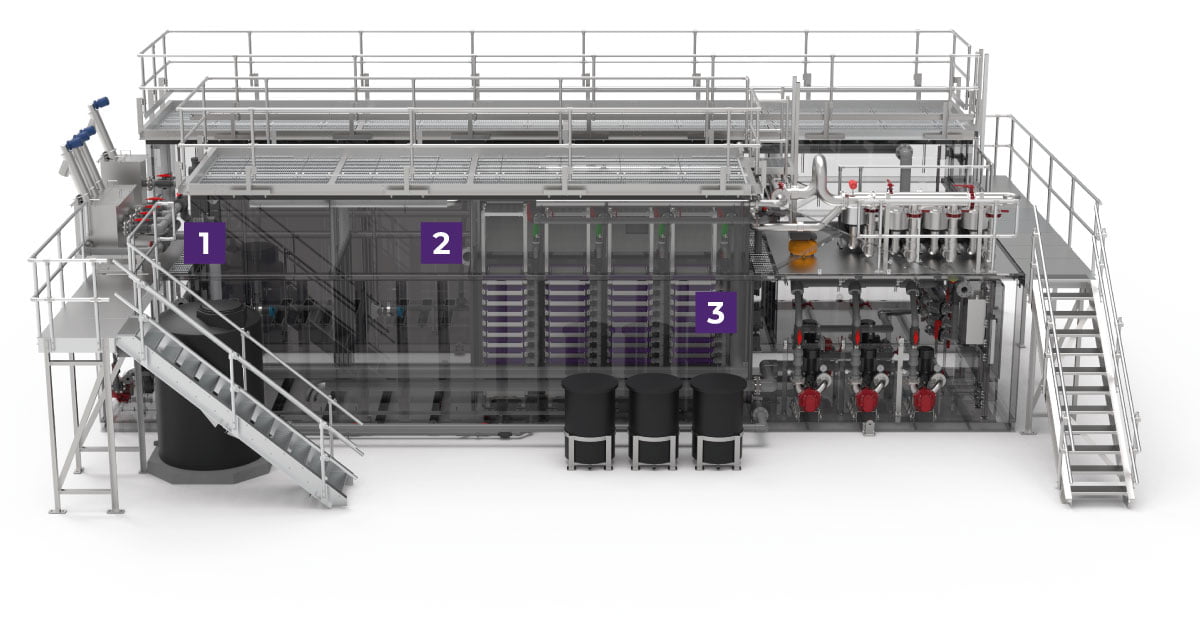

Fine & Coarse Screens

Biological Treatment Zones

SiC Membranes

Equipment Decks

Walkways and Ladders

ecoBLOX-micro systems are efficient package solutions for wastewater treatment. Designed and engineered for simple operation.

The systems can be configured to site condition needs and treatment goals. They include influent screening, biologically treatment, and SiC membranes filtration to produce reuse quality effluent.

The units are completely skid mounted and easy to setup with a few field connections for piping and electrical connections with integrated control panel.

KEY FEATURES & BENEFITS:

- Ready-to-Operate MBR System

- Small footprint

- Easily transported and located

Ideally suited for housing developments, isolated communities, military camps, shopping malls, golf courses, resorts, casinos, sewer mining (scalping), some industrial, reuse and more.

DID YOU KNOW?

Less than half of the polymeric MBRs installed by Ovivo reached 10-year membrane life.