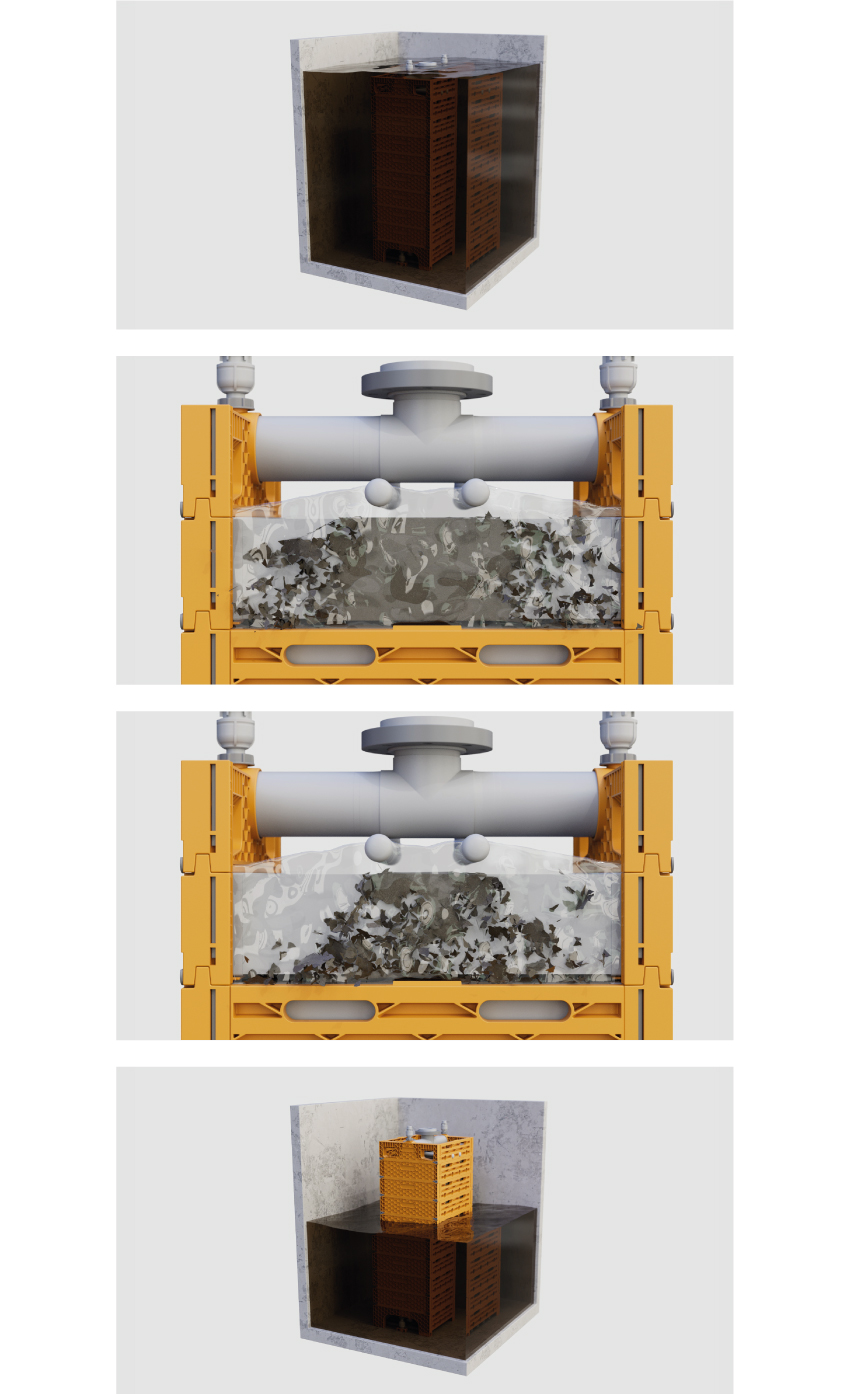

SiC Blox Modules consist of SiC plates configured into two different module designs

Each module design was developed to meet the exact needs of their respective applications. Wastewater applications like MBR create an abusive, high solids environment where product durability is paramount. Other applications like drinking water, where fouling is at a minimum require module designs that shrink footprint and costs.

Extreme

applications

like MBR and

sludge

thickening

applications

like MBR and

sludge

thickening

SiC Blox Modules consist of SiC plates configured into two different module designs

MODULE INTRODUCTION

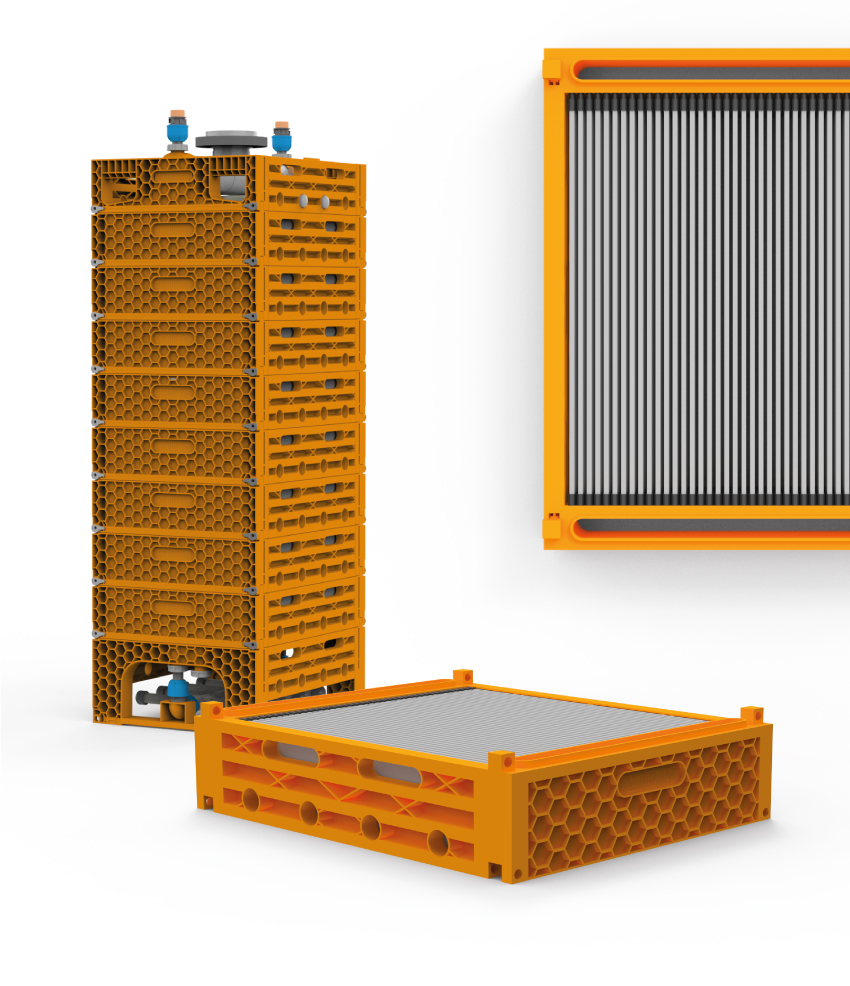

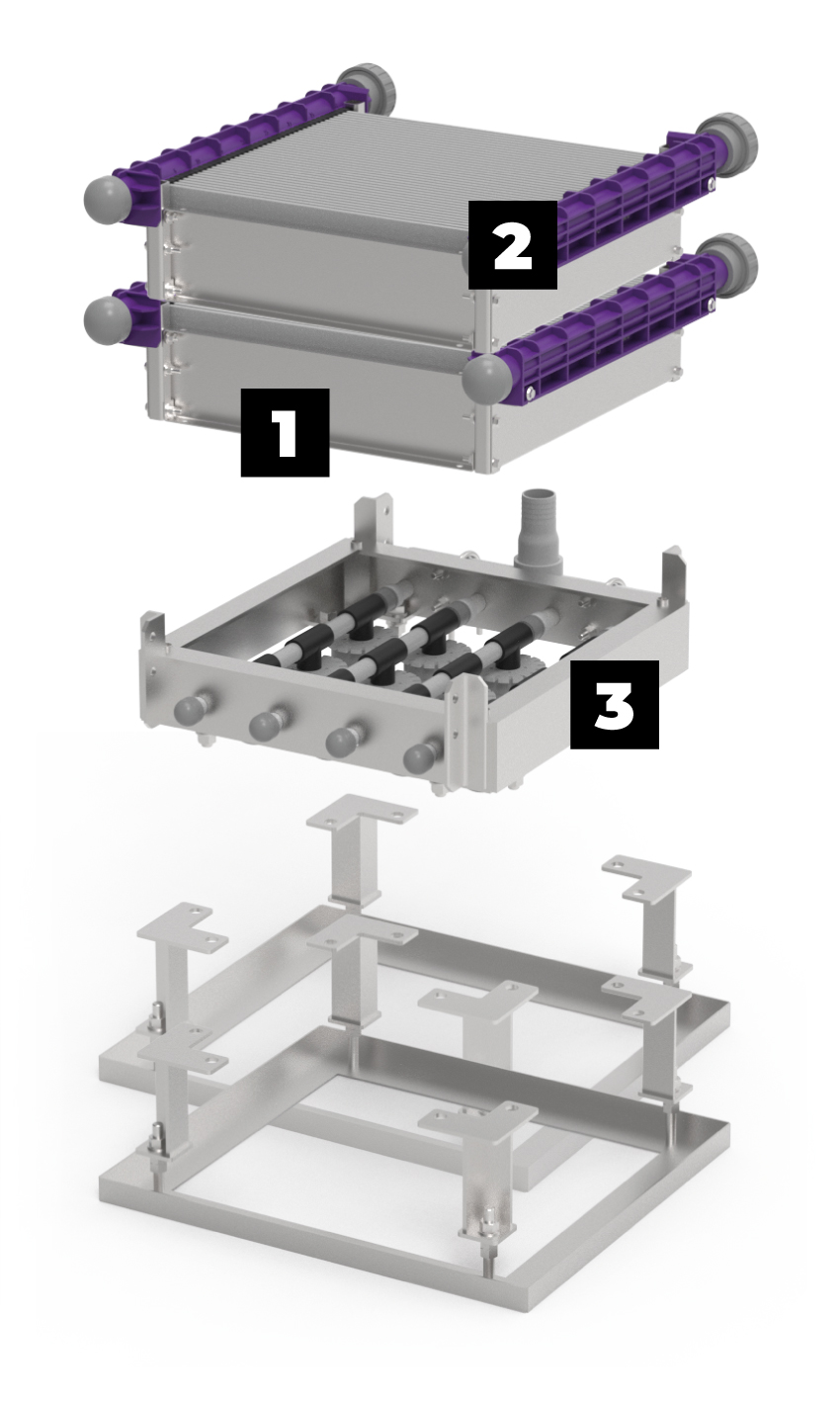

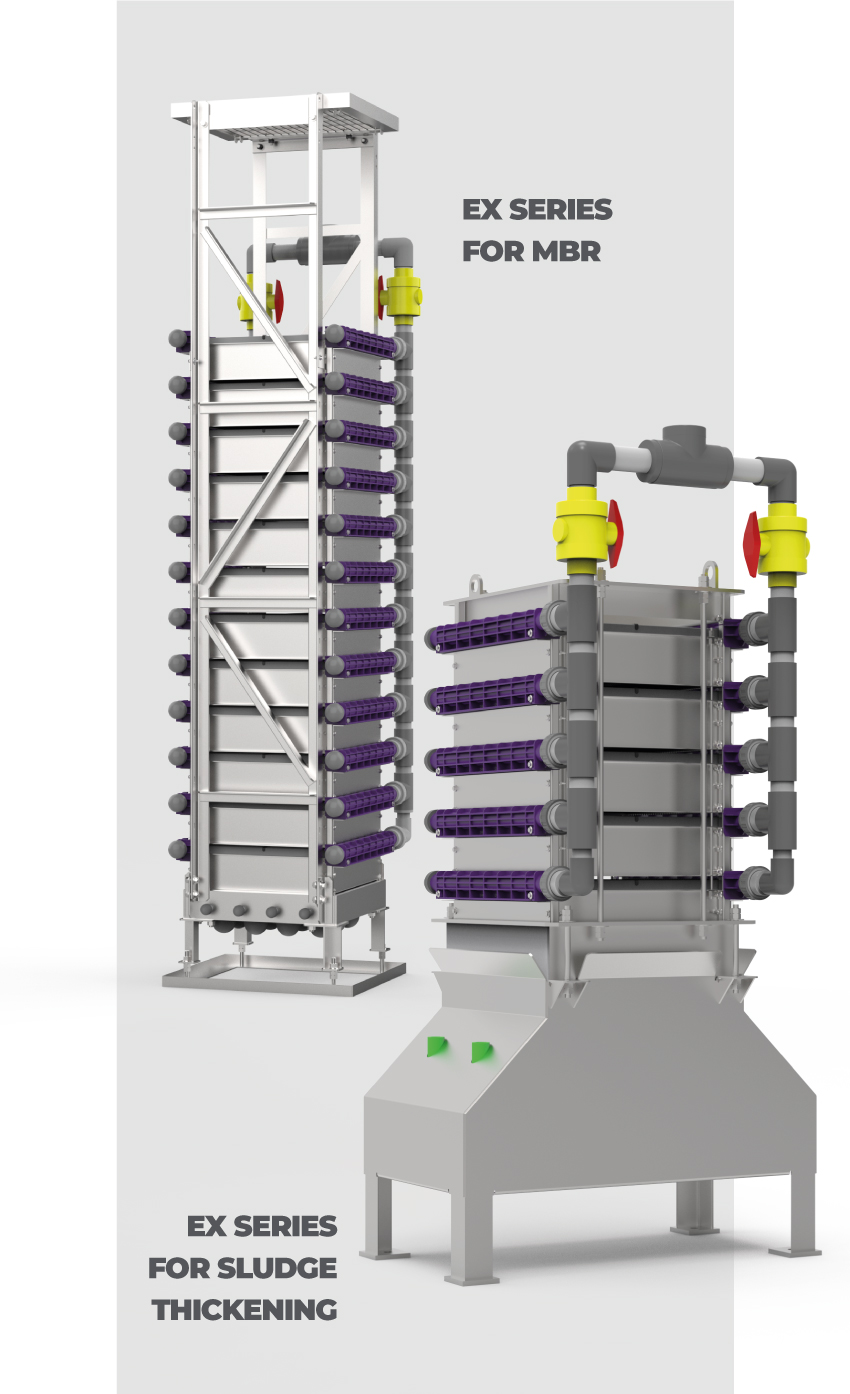

The design philosophy for each module is exactly the same: modular sub-units that can be configured to meet the needs of any project. SiC BLOX Modules can be easily stacked to fit any basin size, creating unprecedented flexibility within the industry. Both the EX and FX series modules have the same basic structure:

1. Diffuser case

2. Membrane module(s)

3. Permeate piping connections

One noticeable difference between the two module types is materials of construction. The EX series module is constructed of stainless steel, providing the necessary structure and strength to survive high mixed liquor environment. The FX Series modules are constructed of plastic, with an emphasis on lightweight and compact capabilities at a low cost.

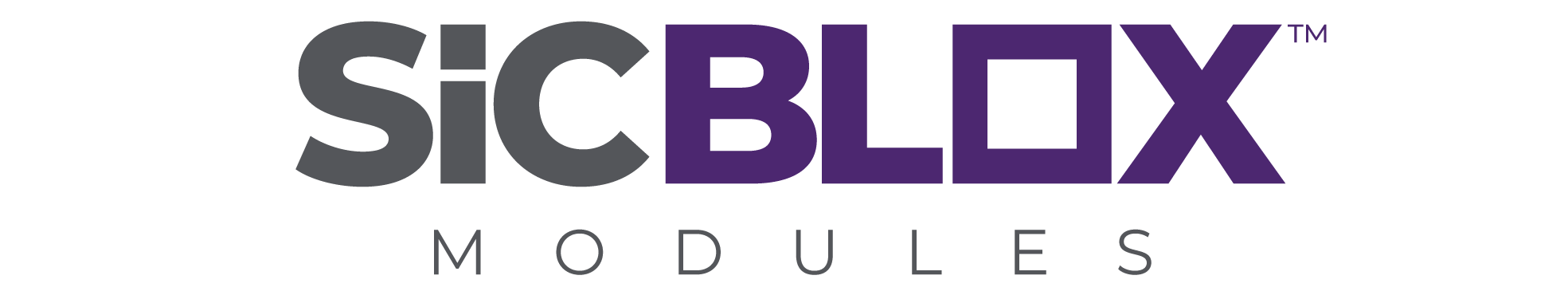

EX Series Modules were developed specifically for very extreme and abusive applications, such as MBR and sludge thickening, due to the numerous mechanical stresses placed on the membranes. Unlike polymerics, EX series modules can also be pressure washed to remove dewatering, ragging, or trash accumulation.

The FX Series Modules were developed for low solids applications like drinking water and tertiary filtration where high flux capabilities are the key drivers. FX series modules also have an automated sprinkler wash system that quickly and effectively cleans the membranes – it’s kind of like sending your membranes through a car wash.